Calculation tool for foundry ladles

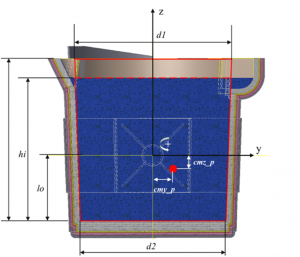

A producer of casting furnaces planned to provide his construction department with a software app to unify and simplify the sizing of foundry ladles and the necessary power unit, especially the gearbox. One important aspect in the construction of these foundry ladles is the fact that the volume of outflowing melt changes depending on the tilt angle. Thus, also the balance point and the moment of inertia are changing.

Our task was to develop a calculation routine which determines all necessary parameters for the construction of foundry ladles. Furthermore, this routine had to be implemented into to commercial CAD software used by the furnace producer.