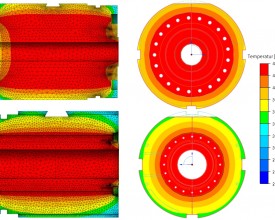

Container heating for isothermal extrusion

The container is the largest heated component during extrusion. Therefore, knowledge about the exact temperature distribution in the container is not only crucial for realizing isothermal extrusion and thus for the profile quality but also for the durability of the container. In modern extrusion containers the heating is accomplished by high power heat cartridges.

In a joint project with a heating specialist and a container manufacturer, we verified what the ideal distance between the extrusion billets and the heaters should be to ensure high extrusion performance. The thermal analysis was performed by computer aided simulations. The results were evaluated in terms of temperature distribution in the extrusion billet and also with respect to stress development in the container. Such so-called thermal stresses are caused by radial temperature differences in the container generated by incorrect positioning of the heating elements. Consideration of these simulated stresses in combination with the material properties of the used hot working steels allowed for the optimum positioning of the heating elements.